All dimensions of specific cables are for reference only and may vary during production.

WIRE KG 4х120

TU U 27.3-33527835-004:2016

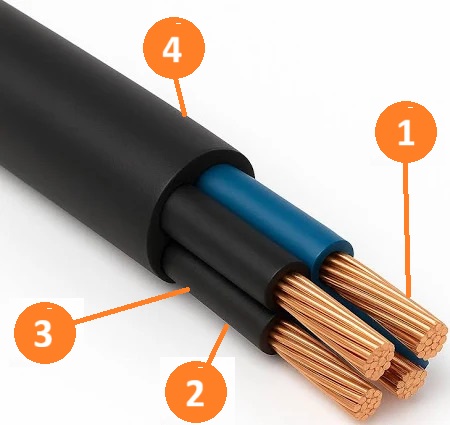

Flexible cable with copper conductors, with insulation and sheath made of thermoplastic elastomer.

The abbreviation KG is deciphered as follows:

CONSTRUCTION

TECHNICAL CHARACTERISTICS

APPLICATION

The main purpose of the KG cable brand is to connect portable tools and mobile electrical devices to the power supply network at a nominal alternating voltage of 660 V with a frequency up to 400 Hz, or nominal direct voltage of 1000 V.

It can be used:

Usually the cable is laid on the ground or on the surface of asphalt or concrete sites. The cable is removed after the completion of works.

The main condition is to avoid significant mechanical impacts on the outer sheath.

The softness of the thermoplastic elastomer, which makes the cable insulation resistant to bending, may cause its destruction due to mechanical action.

There are restrictions on the use of KG brand cables – they cannot be used as stationary underground laying or in lifting and transport equipment.

This is due to the fact that its insulation is very sensitive to mechanical loads.

For example, a vehicle passing over it or a heavy object falling on the wire may disable it.

Such impacts are very critical for multi-wire products, especially those without external protection.

The presence of external protection enhances the protective properties of the cable.

Rainwater and dirt do not affect the performance of products with flexible insulation and sheath made of thermoplastic elastomer.

Installation and Operation Guidelines

Transportation and Storage

Information on Measures to be Taken in Case of Malfunction

The sale of cable products and the measures to be taken when a defect (non-conformity) of a cable product is detected are carried out in accordance with the concluded contract.

Why it is worth buying KG 4х120 cable from “Energoalliance”

Buying cable products wholesale and retail is more profitable directly from the manufacturer. “Energoalliance” is one of the industry leaders. The company has been known on the market since 2005 and offers certified products at an affordable price. The assortment includes power, installation, and control cables. We cooperate with electrical installation companies, utilities, factories, and individuals. The company works with clients from Ukraine, CIS, and Europe, offering comfortable individual terms of cooperation. The delivery price depends on the current tariffs of the postal service.