CABLES VVGng, VVGng-LS(ngd), VVGng-P, VVGng-LS(ngd)-P

TU U 27.3-33527835-003:2015

Power cable with PVC insulation and sheath, low fire hazard, for rated voltage of 660 V and 1000 V, frequency 50 Hz.

The abbreviation VVGng-LS-P means:

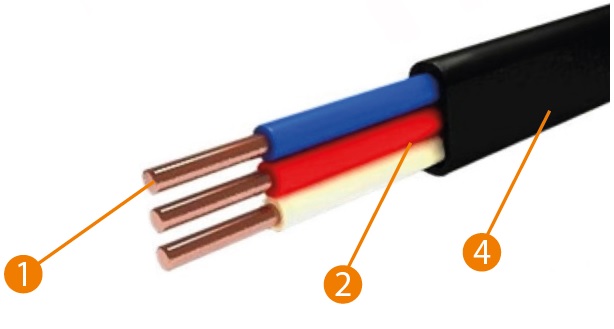

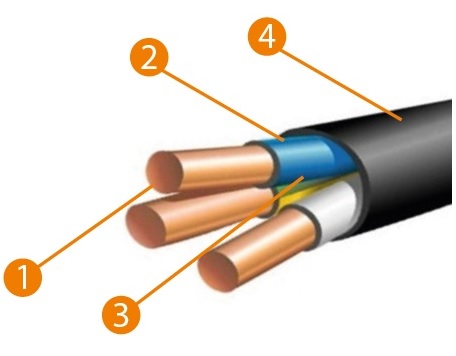

STRUCTURE

| Cable types |

Number of conductors |

Rated voltage, kV | |

|---|---|---|---|

| 0.66 | 1.0 | ||

| Nominal cross-section, mm² | |||

| VVGng | 1 | 1.5–50 | 1.5–800 |

| 2, 3, 4, 5 | 1.5–50 | 1.5–240 | |

| VVGng-P | 2, 3, 4 | 1.5–16 | 1.5–16 |

| Insulation color | Letter code |

|---|---|

| white (uncolored) or gray | B |

| yellow or orange or violet | G |

| red or pink | K |

| blue or light blue | S |

| green | Z |

| brown | Kc |

| black | C |

| green-yellow | Z-G |

TECHNICAL CHARACTERISTICS

Operating ambient temperature: from -50°C to +50°C.

Maximum permissible conductor temperature during operation: +70°C.

DC resistance of conductors per 1 km at 20°C complies with DSTU EN 60228.

Insulation resistance per 1 km at operating temperature of 70°C – not less than 5 kΩ.

Test voltage (AC 50 Hz): 3000 V for 0.66 kV cables and 3500 V for 1.0 kV cables for 10 minutes.

Minimum bending radius during installation – 8 cable diameters.

Manufacturing length – not less than 200 meters.

Warranty period – 5 years from commissioning.

APPLICATION

Cables are designed for transmission and distribution of electrical energy in fixed installations with rated voltage of 660 V and 1000 V, frequency 50 Hz.

Approximate diameter and weight of 1 km of VVGng-P cable (0.66 V) (for reference)

| NUMBER AND CROSS-SECTION OF CONDUCTORS, mm² |

NOMINAL OUTER DIAMETER, mm |

APPROXIMATE WEIGHT OF 1 km, kg |

|---|---|---|

| 4x2.5+1x1.5 | 11 | 204 |

| 4x4.0+1x2.5 | 12.9 | 291 |

| 4x6.0+1x4.0 | 14.2 | 396 |

| 4x10+1x6.0 | 17.4 | 609 |

| 4x16+1x10 | 21.9 | 944 |

| 4x25+1x10 | 26.9 | 1413 |

| 4x25+1x16 | 26.9 | 1474 |

| 4x35+1x16 | 30 | 1899 |

| 4x35+1x25 | 30 | 1996 |

| 4x50+1x25 | 35 | 2595 |

| 5x1.5 | 10 | 155 |

| 5x2.5 | 11 | 212 |

| 5x4.0 | 12.9 | 307 |

| 5x6.0 | 14.2 | 416 |

| 5x10 | 17.4 | 651 |

| 5x16 | 21.9 | 1019 |

| 5x25 | 26.9 | 1569 |

| 5x35 | 30 | 2118 |

| 5x50x10 | 35 | 2873 |

Why it’s worth buying VVGng, VVGng-LS(ngd), VVGng-P, VVGng-LS(ngd)-P cables from Energoalliance

Buying cable products wholesale or retail is most profitable directly from the manufacturer. «Energoalliance» is one of the market leaders. The company has been operating since 2005 and offers certified products at affordable prices. The assortment includes power, installation, and control cables. We cooperate with electrical installation companies, utilities, industrial enterprises, and individuals. The company serves customers in Ukraine, CIS countries, and Europe, offering favorable and personalized cooperation conditions. Delivery cost depends on current postal service rates.